Our Blog

Exciting News!

We’re thrilled to launch our new partnership with MIE Supply in Odessa, Texas!

UniArmour products are now available through MIE’s brand-new Odessa warehouse offering faster delivery, stronger support, and reliable solutions right where the industry needs them most.

Our high-quality product line includes:

• 5.5” Casing Buttress Protectors

• PH-6 Tubing Protectors

• EUE Tubing Protectors

• Sucker Rod Protectors

• Pipe Chocks

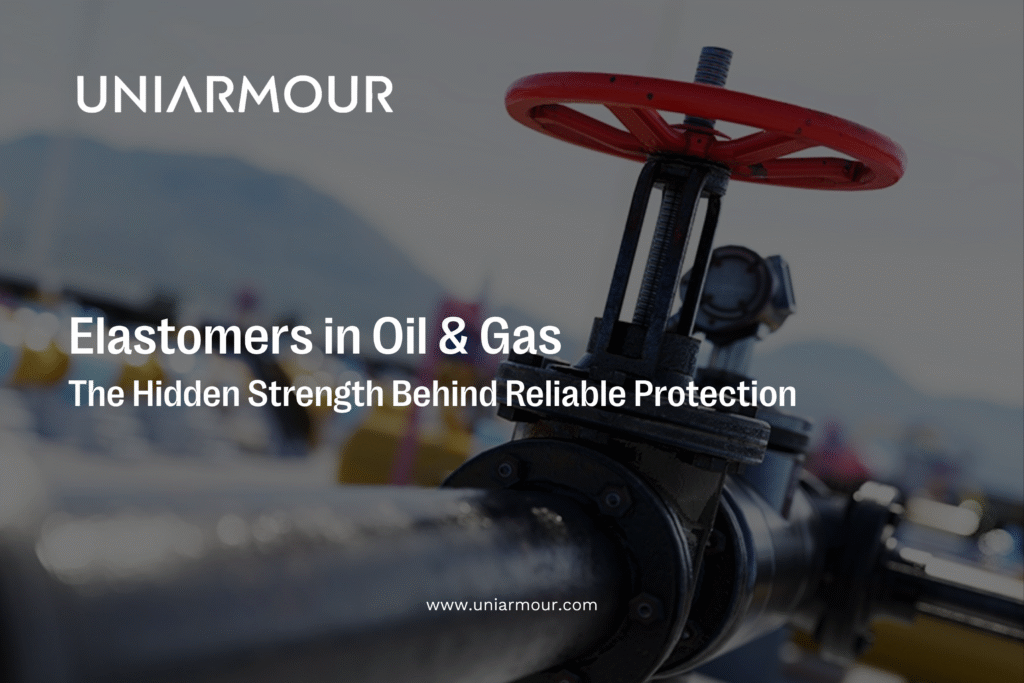

Elastomers in Oil & Gas: The Hidden Strength Behind Reliable Protection

Introduction

In oil and gas operations, where equipment faces extreme pressure, temperature, and mechanical stress, the smallest components can make the biggest difference. Among these, elastomer-based parts produced through rubber molding play a vital yet often underestimated role.

At UniArmour, we integrate high-performance elastomers into our protection systems to deliver superior sealing, shock absorption, and environmental resistance ensuring your operations stay safe and efficient, even in the harshest environments.

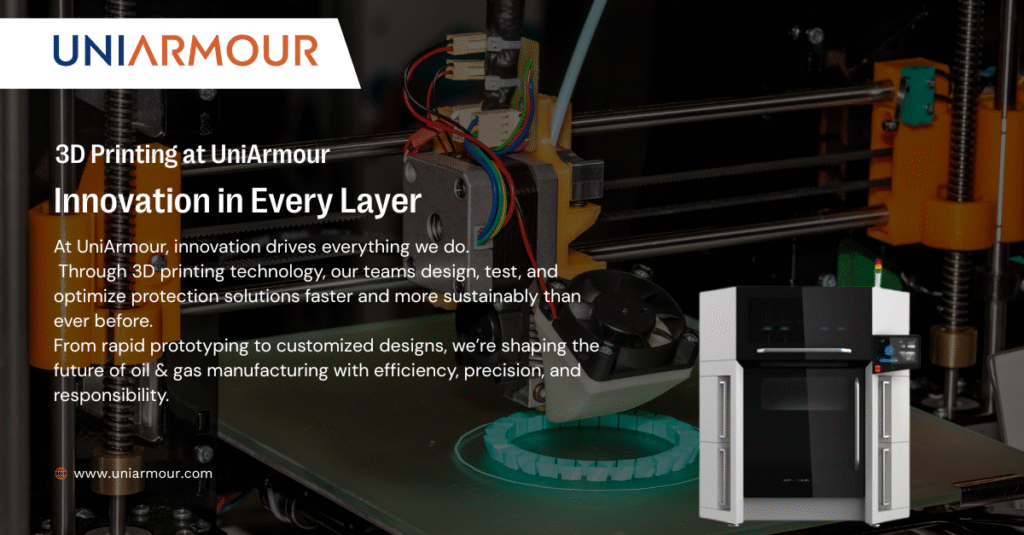

read more…How UniArmour Uses 3D Printing to Drive Innovation in Oil & Gas ?

🔍 Innovation at the Core

At UniArmour, innovation isn’t just a value — it’s part of how we build every product. One of the technologies helping us push boundaries is 3D printing (additive manufacturing). It allows our engineering teams to move faster, test smarter, and deliver better-performing protection solutions for the oil and gas industry.

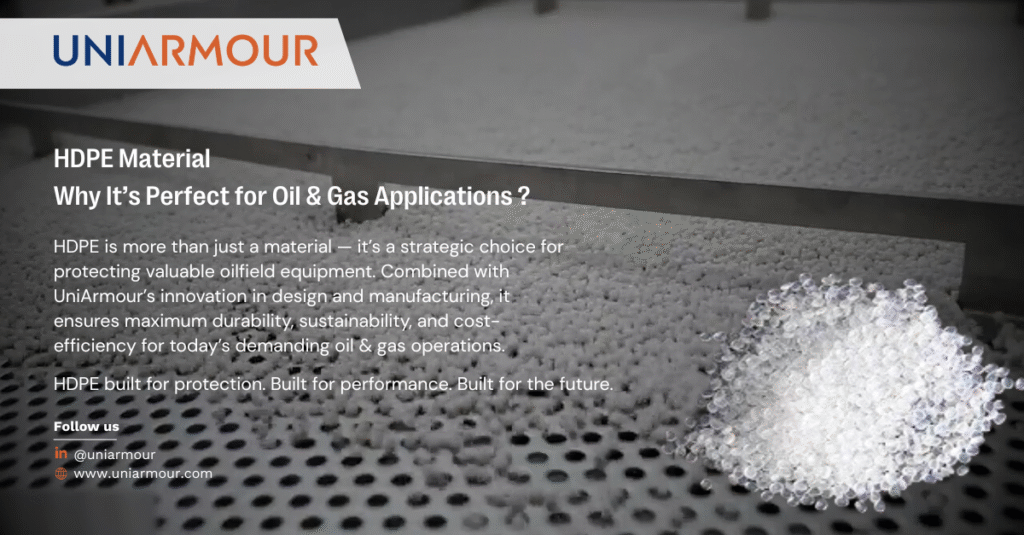

read more…HDPE Material: Why It’s Perfect for Oil & Gas Applications ?

In oil & gas operations, components face extreme conditions: impact, corrosion, handling stress, and harsh environments. That’s why choosing the right material for critical protection products like thread protectors is essential. One material stands out: HDPE (High-Density Polyethylene).

read more…Pipe Protection & Downhole Technologies

Manufacturing capabilities in USA and Egypt

Uniarmour offers products that serve the global market for OCTG, tubings, sucker rods, perforating guns in addition to large diameter protectors for subsea operations.

The company’s high-density polyethylene and proprietary composites products are easily recyclable, improve functionality and provide cost benefits.